We Service All Water Softeners and We Sell Parts for All Water Softeners

We will service all water softeners.

There was a survey that was performed in connection with the Central Arizona Salinity Study (CASS) which studied water softener penetration in the Phoenix Arizona metro area. At the time the survey was conducted (2004) it was estimated that the penetration of water softeners was 51 percent – for homes built since the year 2000 – and it was 47 percent for homes built in the 1990’s. The CASS is now estimating that about 26 percent of all homes in the Phoenix area have water softeners. (this is my information source: e-mail dated 09.09.13 from David Perry ‘Executive Director of the Arizona Water Quality Association’)

In our effort to be the best water conditioning company in the world; we want to become service experts on all water softener units and all water filtration units ‘residential and commercial’. We wish to carry the most common parts (with an emphasis on recycled parts) for these units and provide service to these units. If we don’t have the parts – we will seek and research the parts and procure them for you. We liken this approach to adopting orphan water treatment equipment. We love the people we meet utilizing this approach. If we can’t fix your unit – we will learn or suggest to you the alternative options to economically provide you soft water. We are very upfront business people and water treatment professionals. We will always tell you that we have developed some unique rental water treatment approaches that represent our three operating tenants: 1. To raise the standard of our water treatment industry 2. To aggrandize our client relationships and 3. To develop a sustainable approach to water treatment that will benefit our client’s budgets and positively impact higher quality results for water treatment in our region.

Our approach is to earn your trust by adding the highest value to your existing water treatment equipment.

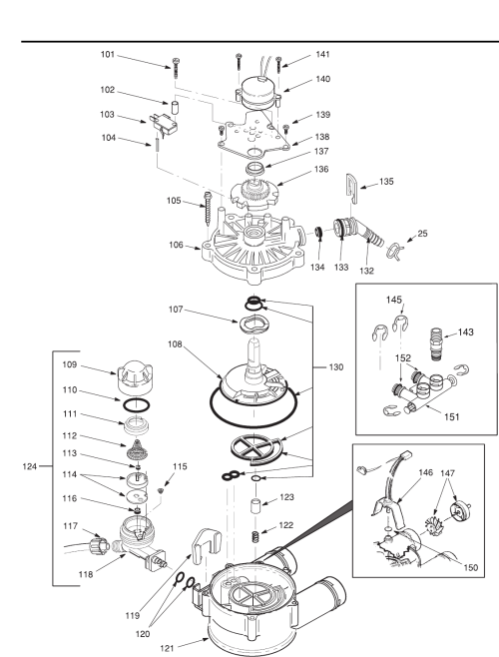

Here are pictures of some of the units we service. Our onus is to continue to increase our water treatment service repertoire and add the pictures of all these different units. If there is a certain type of water treatment equipment being installed in the Phoenix Metro area of Arizona; we will seek to own it – explicate this – dissect this and sell the parts. Once we learn the unit – we will want more of these units (to gain more individual parts on each different type of unit) to share with you. We hope to increase your water treatment value and experience with this approach.

#1

08.08.14 These are two images of Clack Water Softeners displayed by Francisco and Marco. We carry all the components and parts to service these water softeners. These are good water softeners. When one of our clients purchase a water softener; this is the brand of valve that we install. We build our own water equipment, deliver, install, service and customer service this equipment. We feel this is one of our success formulas. We are a one stop shop. The same people you talk to on the phone will be the same people who build your unit and install and service this unit for you.

11.18.15 12:34 PM

Clack WS 1 water softener valve – parts and operational manual

Bypass Valve

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control valve repairs or maintenance. The WS 1 bypass valve is particularly unique in the water treatment industry due to its versatility and state of the art design features. The 1″ full flow bypass valve incorporates four positions including a diagnostic position that allows service personal to work on a pressurized system while still providing untreated bypass water to the facility or residence. It’s completely non-metallic, all plastic design allows for easy access and serviceability without the need for tools.

The bypass body and rotors are glass filled Noryl and the nuts and caps are glass filled polypropylene. All seals are self-lubricating EPDM to help prevent valve seizing after long periods of non-use. Internal 0-rings can easily be replaced if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow shaped handles. The handles identity the flow direction of the water. The plug valves enable the bypass valve to operate in four positions.

- Normal Operation Position: The inlet and outlet handles point in the direction of flow indicated by the engraved arrows on the control valve. Water flows through the control valve during normal operation and this position also allows the control valve to isolate the media bed during the regeneration cycle.

2. Bypass Position: The inlet and outlet handles point to the center of the bypass, the control valve in isolated from the water pressure contained in the plumbing system. Untreated water is supplied to the plumbing system.

2. Bypass Position: The inlet and outlet handles point to the center of the bypass, the control valve in isolated from the water pressure contained in the plumbing system. Untreated water is supplied to the plumbing system.

3. Diagnostic Position: The inlet handle points in the direction of flow and the outlet handle points to the center of bypass valve, system water pressure is allowed to the control valve and the plumbiiig system while not allowing water to exit from the control valve to the plumbing.

3. Diagnostic Position: The inlet handle points in the direction of flow and the outlet handle points to the center of bypass valve, system water pressure is allowed to the control valve and the plumbiiig system while not allowing water to exit from the control valve to the plumbing.

4. Shut Off Position: The inlet handle points to the center of the bypass valve and the outlet handle points in the direction of flow, the water is shut off to the plumbing system. If water is available on the outlet side of the softener it is an indication of water bypass around the system (i.e. a plumbing connection somewhere in the building bypasses the system).

4. Shut Off Position: The inlet handle points to the center of the bypass valve and the outlet handle points in the direction of flow, the water is shut off to the plumbing system. If water is available on the outlet side of the softener it is an indication of water bypass around the system (i.e. a plumbing connection somewhere in the building bypasses the system).

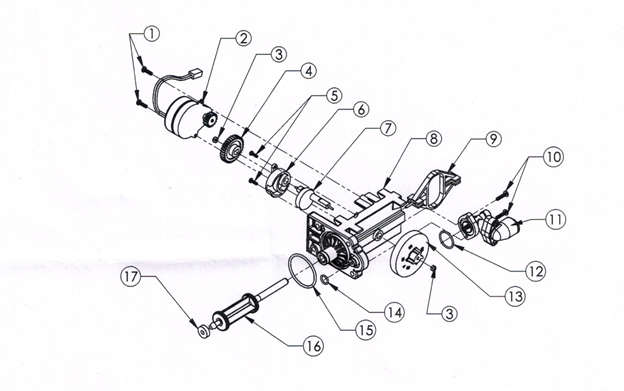

Front Cover and Drive Assembly for WS1 Clack water softener valve

Drawing No. Order No. Description Quantity

1 V3175-01 WS 1 Front Cover ASY 1

2 V3107-01 WS 1 Motor 1

3 V3106-01 WS 1 Drive Bracket & Spring Clip 1

4 V3108 WS 1 PC Board 1

5 V3110 WS 1 Drive Geart 12×36 3

6 V3109 WS 1 Drive Gear Cover

V3002 WS 1 Drive ASY

Not Shown 173186 WS Transformer ttOV-t2V

* Drawing number parts 2 through 6 may be purchased as a complete assembly, part ‘5/3002.

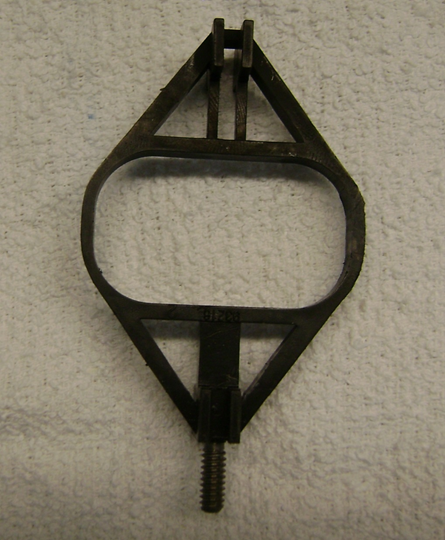

Drive Cap Assembly, Dowoflow Piston, Upflow Piston, Regenerant Piston and Spacer Stack Assembly for WS1 Clack Water Softener

Drawing No. Order No. Description Quantity

1 V3005 WSI Spacer Stack Assembly 1

2 V3004 Drive Cap ASY 1

3 V3135 0-ring 228 1

4a V3011* WS 1 Piston Downflow ASY 1

4b V301 1-01 WS1 Piston Upflow ASY 1

5 V3174 WS 1 Regenerant Piston 1

6 V3180 0-ring 337 1

V3O11 is labeled with DN and V3011-01 is labeled with UP.

Note: The regenerant piston is not used in backwash only applications.

Injector Cap, Injector Screen, Injector, Plug and 0-Ring

Drawing No. Order No. Description Quantity

1 V3176 Injector Cap 1

2 V3152 0-ring 135 1

3 V3177 Injector Screen 1

4 V3010-IZ WS 1 Injector ASY Z Plug 1

V3010-1A WS1 INJECTOR ASYABLACK

V3010-IB WS1 INJECFORASY B BROWN

V3010-IC WS1 INJECTOR ASY C VIOLET

V30I0-ID WS1 INJECTOR ASYDRED

V3010-1E WS1 INJECTOR ASYE WHITE

5 V3010-IF WS1 INJECTOR ASYFBLUE

V3010-IG WS1 INJECTOR ASY G YELLOW

V3010-1H WS1 INJECTOR ASYHGREEN

V3010-1I WS1 INJECTOR ASY I ORANGE

V3010-1J WS1 INJECTOR ASY J LIGHT BLUE

V3010-1K WS1 INJECTOR ASY K LIGHT GREEN

Not Shown V3170 0-ring011

Not Shown V3171 0-ring 013

*The injector ping and the injector each contain one 011 (tower) and 013 (upper) 0-ring.

Note: For downflow, injector is located in the down hole and injector plug in the up hole. For a filter that only backwashes, injector plugs are located in both holes, and regenerant piston must be removed.

Refill and Refill Port Plug

Drawing No Order No. Description Quantity

1 V3195-01 WS Refill Port Plug ASY This part is required for backwash

only systems

2 H4615 Elbow Locking Clip

3 JCP-P-6 Polytube insert 3/8

4 JCPG-6PBLK Nut 3/8

5 014613 Elbow Cap 318

6 V3163 0-ring019 1

7 V3165_01* WS 1 RFC Retainer ASY

8 V3182 WS1RFC 1

Not Shown H4650 Elbow 1/2″ with nut and insert Option

Drain Line-3/4″

Drawing No. Order No. Description Quantity

I 114615 Elbow LockingClip 1

2 PKPIOTS8-BULK Polytube insert 5/8 Option

3 V3I92 WS1 Nut 3/4 Drain Elbow Option

4 V3158-01 WS 1 Drain Elbow ¾ Male ASY 1

5 V3163 0-ring 019 1

6 V3159-Ol WS1 DLFC Rotairrr ASY 1

VS 162-007 WS DLFC 0.7 rpm for 3/4

V3162-010 WS1 DLFC I.) Gpm for 3/4

V3162-013 WS 1 DLFC 1.3 gym for 3/4

V3162-0I7 WS1 DLFC l.7gimc for 3/4 0ne

V3162-022 WS1 DLFC 2.2 ppm for 3/4 DLFC

V3162-027 WS1 DLFC 2.7 gpm for /3/4 must be

used if ¾”

fitting is used

7 V3I62-032 WS1 DLFC 3.2 fgpm or 3/4

VS l62-042 WS1 DLFC 4.2 gym for 314

V3162-053 WS1 DLPC 5.3 gym for 3/4

V3162-065 WS1 DLFC 6.5 gym for 3/4

VS 3162-075 6’Sl DLFC 7.5 gym for 3/4

V3162-090 WSI DLFC 9.0 ppm for 3/4

V3162-I00 WSI DLFC 10.0 gpm for 3/4

Valves are shipped without drain line flow control (DLFC) —install DLPC before using. Valves are shipped without ¾” nut for drain elbow (polytube installation only) and 5/8″ polytube installation only).

Drawing No. Order No. Description Quantity

1 H4615 Elbow Locking Clip 1

2 V3008-02 WS Drain FTG 1 Straight 1

3* V3166 WS 1 Drain FTC Body 1 1

4° V3167 WS1 Drain FTG Adaptor 1 1

5° V3163 0-ring 019 1

6° V3150 WS1 Split Ring 1

7° V3151 WS1 Nut 1” QC 1

8* V3105 O-ring 215 1

V3190-090 WS 1 DLFC 9.0 gpm for 1

V5190-100 WS 1 DLFC 10.0 gpm for 1 One

V3190-110 WS 1 DLFC 11.0 gpm for 1 DLFC

V3190-130 WS 1 DLFC 13.0 gpm for 1 must be

V3190-150 WS1 DLFC 15.0 gym for 1 used if

V3190-170 WS 1 DLFC 17.0 gym for 1 1″ fitting

V3190-200 WS 1 DLFC 20.0 gym for 1 is used

V3190-250 WS1 DLFC 25.0 gym for 1

Can be ordered us a set order number V3008-02, description: WS1 Drain FTG 1 Straight.

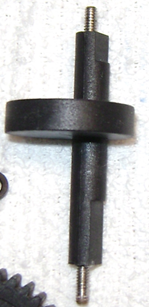

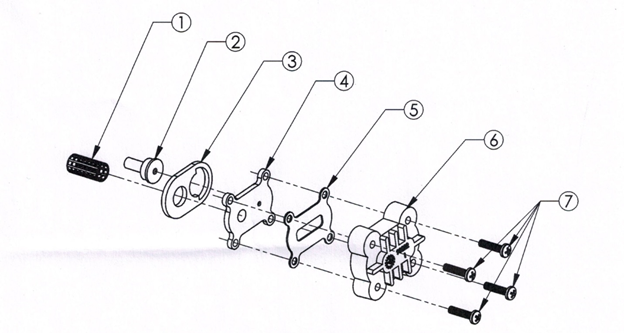

Water Meter and Meter Plug

Drawing No. Order No. Description Quantity

1 V3151 WS1 Nut 1” QC 1

2 V3003° WS1 Meter ASY 1

3 V3118-01 WS1 Turbine ASY 1

4 V3105 0-ring 215 1

5 V3003-01 WS 1 Meter Plug ASY 1

*Order number V3003 includes V3118-01 and V3105.

Installation Fitting Assemblies

Order No: V3007

Description: WS1 Fitting 1” PVC Male NPT Elbow Assembly

Drawing no order no description quantity

1 V3151 WS1 Nut 1 “ Quick Connect 2

2 V3l50 WS 1 Split Ring 2

3 V3105 O-Ring 215 2

4 V3149 WS1 Fitting 1 PVC Male NPT Elbow 2

Order No: V3007

Description: WS1 Fitting 1” PVC Male NPT Elbow Assembly

Drawing no order no description quantity

1 V3151 WS1 Nut 1” Quick Connect 2

2 V3150 WS1 Split Ring 2

3 V3105 O Ring 215 2

4 V3149 WS1 Fitting 1 PVC Male NPT Elbow 2

Order No: V3507-02

Description: WSI Fitting 1″ Brass Sweat Assembly

Drawing no order no description quantity

1 V3151 WS1 Nut 1” Quick Connect 2

2 V3150 WS1 Split Ring 2

3 V3105 O-Ring215 2

4 V3188 WS1 Fitting 1” Brass Sweet 2

Order No: V3007-03

Description: WSJ Fitting 3/4’” Brass Sweat Assembly

Drawing no order no description quantity

1 V3151 WS1 Nut 1” Quick Connect 2

2 V3150 WS1 Split Ring 2

3 V3105 O-Ring 215 2

4 V3188-01 WS 1 Fitting ¾ Brass Sweat 2

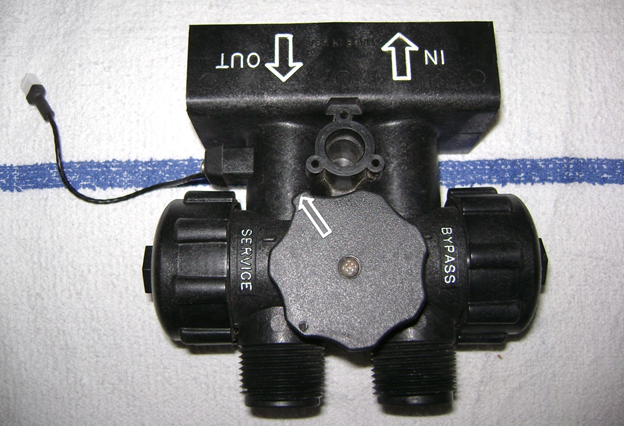

Bypass Valve

Drawing No. Order No. Description Quantity

1 V3151 WS1 Nut 1″ Quick Connect 2

2 V3150 WS1 Split Ring 2

3 V3105 O-Ring 2I5 2

4 V3145 WS1 Bypass 1″ Rotor 2

5 V3146 WS1 Bypass Cap 2

6 V3147 WS1 Bypass Handle 2

7 V3148 WS1 Bypass Rotor Seal Retainer 2

8 V3152 0 -ring 135 2

9 V3152 0-ring 112 2

10 V3156 O-ring 214 2

(Not Shown) Order No. V3191-01, Description: WS1 Bypass Vertical Adapter Assembly

Order No. Description Quantity

V3151 WS1 Nut 1″ Quick Connect 2

V3150 WS1 Split Ring 2

V3105 0-Ring 215 2

V3191-01 WS1 Bypass Vertical Adapter Assembly 2

Service Instructions

Drive Assembly

Remove the valve cover to seems the drive assembly

Disconnect the power source plug (black wire) from the PC board prior to disconnecting the motor or water meter plugs from the PC board. The motor plug connects to the two-pin jack on the left-hand side of the PC board. The power source plug connects to the four-pinjack. The four-pinjack is between the two-pin and three-pin jacks. The water meter plug (gray wire) connects to the three-pin jack on the far right-hand side of the PC board.

The PC board can be removed separately from the drive bracket but it is not recommended. Do not attempt to remove the display panel from the PC board. Handle the board by the edges. To remove the PC board from the drive bracket, unplug the power, water meter and motor plugs from the PC board. Lift the middle latch along the top of the drive bracket while pulling outward on the top of the PC board. The drive bracket has two plastic pins that fit into the holes on the lower edge of the PC board. Once the PC board is tilted about 45 from the drive bracket it can be lifted off of these pins. To reinstall the PC board, position the lower edge of the PC board so that the holes in the PC board lineup with the plastic pins. Push the top of the PC board towards the valve until it snaps under the middle latch, weave the power and water meter wires into the holders and reconnect the motor, water meter and power plugs.

The drive bracket must be removed to access the drive cap assembly and pistons or the drive gear cover. It is not necessary to remove the PC board from the drive bracket to remove the drive bracket. To remove the drive bracket start by removing the plugs for the power source and the water meter. Unweave the wires from the side holders. Two tabs on the top of the drive back plate hold the drive bracket in place. Simultaneously lift the two tabs and gently ease the tap of the drive bracket towards your body. The lower edge of the drive bracket has two notches that rest on the drive back plate. Lift up and outward on the drive bracket to disengage

the notches.

To reassemble seat the bottom of the drive bracket so the notches are engaged at the bottom of the drive back plate. Push the top of the drive bracket towards the two latches. The drive bracket may have to be lifted slightly to let the threaded piston rod pass through the hole In the drive bracket Maintain a slight engaging force on top of the drive bracket while deflecting the bracket slightly to the left by pressing on the side of the upper right corner. This helps the drive gears mesh with the drive cap assembly. The drive bracket is properly seated when it snaps under the latches on the drive back plate. If resistance is felt before latching, then notches are not filly engaged, the piston rod is not in hole, the wires are jammed between the drive bracket and drive buck plate, or the gear is not engaging the drive cap assembly.

To inspect drive gears, the drive gear cover needs to be removed. The drive gear cover is held in place on the drive bracket by three clips. The largest of the three clips is always orientated to the bottom of the drive bracket. Before trying to remove the drive gear cover, the drive bracket must be removed from the drive back plate. The drive gear cover can be removed from the drive bracket without removing the motor or the PC board. Simultaneously, push in and down on the large clip at the bottom and the clip on the left-hand side of the drive bracket behind the PC board. Keep your other fingers behind the drive gear cover so the drive gears do not drop on the ground.

Replace broken or damaged drive gears. Do not lubricate any of the gears. Avoid getting any foreign matter on the reflective coating became dirt or oils may interfere with pulse counting.

The drive gear cover only fits on one way, with the large clip orientated towards the bottom. If all three clips are outside of the gear shroud on the drive bracket the drive gear cover slips easily into place.

The drive bracket does not need to be removed from the drive plate if the motor needs to be removed. To remove the motor, disconnect the power and motor plugs from the jacks on the PC board. Move the spring clip loop to the right and hold. Rotate the motor at least a% turn in either direction before gently pulling on the wire connectors to remove the motor. Pulling directly on the wires without rotating the motor may break the wires off the motor.

Replace the motor if necessary. Do not lubricate the motor or the gears. When reinstalling the motor gently turn the motor while inserting so that the gear on the motor meshes with the gears under the drive gear cover and the small plastic bulge engages one of the slots on the motor housing. Reconnect the motor plug to the two pronged jack on the lower left hand side of the PC board. If motor will not easily engage with drive gear when reinstalling, lift and slightly rotate motor before reinserting.

Replace the valve cover. After completing any valve maintenance, press and hold NEXT and REGEN bottom for 3 seconds or unplug power source jack (black wire) and plug back in. This resets the electronics and establishes the service piston position. The display should flash all wording, then flash the soft ware version (e.g. 154) and then reset the valve to the service position.

Drive Can Assembly Main Piston and Regenerant Piston

The drive assembly must be removed to access the drive cap assembly. The drive cap assembly most be removed to access the piston(s). The drive cap assembly is threaded into the control valve body and seals with an o-ring. To remove the drive cap assembly use the special plastic wrench or insert a ¼’ to /i flat bladed screwdriver into one of the slots around the top 2″ of the drive cap assembly so it engages the notches molded into the drive back plate around the top 2′ of the piston cavity. The notches are visible through the holes. Lever the screwdriver so the drive cap assembly turns counter clockwise. Once loosened unscrew the drive cap assembly by hand and pull straight out.

The drive cap assembly contains the drive cap, the main drive gear, drive cap spline, piston rod and various other parts that should not be dissembled in the field. The only replaceable part on the drive cap assembly is the 0-ring. Attached to the drive cap assembly is the main piston (down flow or up flow) and if a regenerant is used, a regenerant piston.

The regenerant piston (the small diameter one behind the main piston) is removed from the main piston by unsnapping it from its latch. Chemically clean in dilute sodium bisulfite or vinegar or replace the regenerant piston if needed. To remove the main down flow or up flow piston fully extend the piston rod and then unsnap the main piston from its latch by pressing on the side with the number. Chemically clean in dilute sodium bisulfite or vinegar or replace the main piston.

Reattach the main piston to the drive cap assembly. Reattach the regenerant piston (if needed) to the main piston. Do not lubricate the piston rod, main piston or regenerant piston. Lubricant will adversely affect the red or clear lip seals. Reinsert the drive cap assembly and piston into the spacer stack assembly and hand tighten the drive cap assembly. Continue to tighten the drive cap assembly using a screwdriver as a ratchet until the black o-ring on the spacer stack assembly is no longer visible through the drain port. Excessive force can break the notches molded into the drive back plate. Make certain that the main drive gear still turns freely. The exact position of the piston is not important as long as the main drive gear turns freely.

Reattach the drive assembly to the control valve and connect all plugs. After completing any valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire) and plug back in. This resets the electronics and establishes the service piston position. The display should flash all wording, then flash the soft ware version (e.g. 154) and then reset the valve to the service position.

spacer stack assembly

To access the spacer slack assembly remove the drive assembly, drive cap assembly and piston. The spacer stack assembly can be removed easily without tools by using thumb and forefinger. Inspect the black 0-rings and red or clear lip seals for wear or damage Replace the entire stack if necessary. The spacer stack assembly has been 100% tested at the factory to insure proper orientation of one way seals. Do not disassemble the stack.

The spacer stack assembly maybe chemically cleaned (dilute sodium bisulfite or vinegar) or wiped with a soft cloth.

The spacer stack assembly can be pushed in to the control valve body bore by hand. Since the spacer stack assembly can be compressed it is easier to use a blunt object (5/8″ to 1-1/8″ in diameter) to push the center of the assembly into the control valve body. – The assembly is properly seated when at least four threads are exposed (approximately 5/8″). Do not force the spacer stack assembly in. The control valve body bore interior can be lubricated with silicone to allow for easy insertion of the entire stack. Do not use silicone or any other type of lubricant on the red or clear lip seals or the piston.

Reattach the drive cap assembly and piston(s) and the drive assembly.

After completing any valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire) and plug back in. This resets the electronics and establishes the service piston position The display should flash all wording, then flash the soft ware version and then reset the valve to the service position.

Injector Can. Screen Injector Plug and Injector

Unscrew the injector cap and lift off. Loosen cap with special plastic wrench or pliers if necessary. Attached to the injector cap is a screen. Remove the screen and clean if fouled.

The plug and/or injector can be pried Out with a small screwdriver. The plug can be wiped clean. If the plug leaks replace the entire plug. The injector consists of a throat and a nozzle. Chemically clean the injector with vinegar or sodium bisulfite. The holes can be blown out with air. Both pieces have small diameter holes that control the flow rates of water to insure that the proper concentration of regenerant is used. Sharp objects, which can score the plastic, should not be used to clean the injector. Scoring the injector or increasing the diameter of the hole could change the operating parameters of the injector.

Two holes are labeled DN and UP. Check for compliance with one of the following:

- for down flow systems, the appropriate size injector in located in the “DM’ hole, a plug is in the “UP” hole and that the piston is a combination of the down flow main piston and the regenerant piston.

- for up flow systems, the appropriate size injector is located in the “UP” hole, a plug is in the “Whole and that the piston is a combination of the up flow main piston and the regenerant piston; or

- for backwash only systems, a plug is in the “DN” hole and in the “UP” hole, and that the piston only has a down flow main piston (the regenerant piston must be removed) and a plug is in the refill flow control position.

Push the plug(s) and/or injectors firmly in place, replace the screen and hand tighten the injector cap.

Refill Flow Contrpl Assembly or-Refill Port Plug

To clean or replace the refill flow control, pull out the elbow-locking clip and then pull straight upon the elbow. Replace the elbow locking clip in the slot so that it is not misplaced. Twist to remove the white flow control retainer. The flow control can be removed by prying upward through the side slots of the retainer with a small blade flat screwdriver.

Chemically clean the flow control or the white flow control retainer using dilute sodium bisulfite or vinegar. Do not me a wire brush. If necessary, replace the flow control, wring on the flow control retainer, or the 0-ring on the elbow.

Reseat the flow control so the rounded end is visible in the flow control. Reseal the white flow control retainer by pushing the retainer into the elbow until the wring seats. Remove locking clip, push down on elbow to reseat and insert locking clip.

Do not use Vaseline, oils, or other unacceptable lubricants on o-rings. A silicon lubricant may be used on the n-ring on the elbow or the white retainer.

Water Meter or Meter Plug

The water meter assembly is connected to the PC board by a wire. If the entire water meter assembly is to be replaced, remove the control valve cover and remove the power source and water meter plugs from the PC board. Unlatch the drive assembly and lean it forward. Unthread the water meter wire from the side of the drive assembly and through the drive back plate. To reinstall, rethread the water meter wire through the drive back plate and the side of the drive assembly. Reattach the drive assembly and the water meter and power plugs.

If no water meter wire is visible, then a plug is installed not a water meter.

The water meter wire does not need to be removed from the PC board if the water meter is only being inspected and cleaned. To remove the water meter assembly, unscrew the meter capon the left side of the control valve. Pliers maybe used to unscrew the nut if necessary.

With the nut removed, a slot at the top of the water meter is visible. Twist a flat blade screwdriver in the slot between the control valve body and the meter. When the meter is part way out it is easy to remove the water meter from the housing. Once the water meter is removed from the control valve body, use your fingers to gently pull forward on the turbine to remove it from the shaft.

Do not use a wire brush to clean. Wipe with a clean cloth or chemically clean in dilute sodium bisulfite or vinegar. The turbine can be immersed in the chemical. Do not immerse electronics. If the turbine is scored or damaged or the bearings on the turbine are worn replace the turbine.

Do not lubricate the turbine shaft. The turbine shaft bearings are prelubricated Do not use Vaseline, oils, or other unacceptable lubricants on the o-ring. A silicon lubricant may be used on the black 0-ring.

Snap the turbine on the shaft and reinsert the water meter into the side slot. Hand tighten the nut. Do not use a pipe wrench to tighten nut.

Bypass Valve

The working parts of the bypass valve are the rotor assemblies that are contained under the bypass valve caps. Before working on the rotors, make sure the system is depressurized. Turn the red arrow shaped handles towards the center of the bypass valve and back to the arrow direction several times to ensure rotor is turning freely.

The nuts and caps are designed to be unscrewed or tightened by hand. If necessary a pliers can be used to unscrew the nut or cap. Do not uses pipe wrench to tighten or loosen nuts or caps. Do not place screwdriver in slots on caps and/or tap with a hammer.

To access the rotor, unscrew the cap and lift the cap, rotor and handle Out as one unit. Twisting the unit as you pull it out will help to remove it more easily. There are three 0-rings: one under the rotor cap, one on the rotor stem and the rotor seal. Replace worn 0-rings. Clean rotor. Reinstall rotor.

When reinstalling the red arrow handles be sure that:

- 0-rings on both rotors face to the right when being viewed from the front of the control valve when the handle pointers are lined up with the control valve body arrows; or

2 Arrows point toward each other in the bypass position.

Since the handles can be pulled off, they could be accidentally reinstalled I 80°° from their correct orientation. To install the red arrow handles correctly, keep the handles pointed in the same direction as the arrows engraved on the control valve body while tightening II bypass valve caps.

After completing any valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire) and plug back in. This resets the electronics and establishes the service piston position. The display should flash all wording, then flash the software version (e.g. 154) and then reset the valve to the service pdsition.

Troubleshooting Procedures

Problem Possible Cause Solution

- Timer does not display time of day

- Transformer unplugged a. Connect power

- No electric power at outlet – b. Repair outlet or use working

outlet

- Defective transformer c. Replace transformer

- Defective PC board d. Replace PC board

- Timer does not display a. Switched outlet a.Use uninterrupted outlet

correct time of day

- Power outage b. Reset time of day

- Defective PC board c. Replace PC board

- No softening/filtering display when water is flowing

- Bypass valve in bypass position a.Put bypass valve in service position

- Meter connection disconnected b. Connect meter to PC board

- Restricted/stalled meter turbine c. Remove meter and check for rotation or foreign

material

- Defective meter d. Replace meter

- Defective PC board e. Replace PC board

- Control valve regenerates at wrong time of day

- Power outages a. Reset control valve to correct time of day

- Time of day not set correctly b. Reset to correct time of day

- Time of regeneration incorrect c. Reset regeneration time

- Control valve set at “ on 0″ d. Check control valve set-up procedure

(immediate regeneration) regeneration time option

- Control valve set at NORMAL + c. Check control valve set-up procedure

on 0 regeneration time option

- ERROR followed by code number

Error Code 1001 -Unable to recognize start of regeneration

Error Code 1002— Unexpected stall

Error Code 1003 – Motor ran to long, limed out trying to reach next cycle position

Error Code 1004- Motor ran to long, timed out trying to reach home position.

If other Error Codes display contact the factory.

- Control valve has just been a. Press NEXT and REGEN for 3

serviced seconds or unplug power source jack

(black wire) and plug back in to reset

control valve

- Foreign matter is lodged in b. Check piston and spacer stack

control valve assembly for foreign matter

- High drive forces on piston c. Replace piston(s) and spacer stack assembly

- Control valve piston not in home position d. Press NEXT and REGEN for 3 seconds or

unplug power source jack (black wire) and

plug back in to reset control valve

- Motor not inserted filly to engage e. Check motor and wiring.

pinion, motor wires broken or disconnected, Replace motor if necessary

motor failure

- Drive gear label dirty or damaged, f.Replace or clean drive gear

missing or broken gear

- Drive bracket incorrectly aligned to back plate g. Resent drive bracket properly

- PC board is damaged or defective h. Replace PC board

i.PC board incorrectly aligned to i.Ensure PC board is correctly snapped

drive bracket onto drive bracket

Problem Possible Cause Solution

- Control valve stalled in regeneration

- Motor not operating a. Replace motor

- No electric power at outlet b. Repair outlet or use working outlet

- Defective transformer c. Replace transformer

- Defective PC board d. Replace PC board

- Broken drive gear or drive cap e. Replace drive gear or drive cap

assembly assembly

- Broken piston retainer f. Replace drive cap assembly

- Broken main or regenerant piston g. Replace main or regenerant piston

- Control valve does not regenerate automatically

when REGEN button is depressed and held a. Transformer unplugged a. Connect transformer

- No electric power at outlet b. Repair outlet or use working outlet

- Broken drive gear or drive cap assembly c. Replace drive gear or drive cap

assembly

- Defective PC board d. Replace PC board

- Control valve does not regenerate automatically but does when REGEN button is depressed

- By-pass valve in bypass position a. Put bypass valve in normal operation

position

- Meter connection disconnected b. Connect meter to PC board

- Restricted/stalled meter turbine c. Remove meter and check for rotation

or foreign matter

- Defective meter d. Replace meter

- Defective PC board . e. Replace PC board

- Set-up error f.Check control valve set-up procedure

- Time of day flashes on and off

- Power has been out more than two a. Reset the time of day

hours, the transformer was

unplugged and then plugged back

into the wall outlet, the

transformer plug was unplugged and then plugged back into the

board or the NEXt and REGEN

buttons were pressed to reset the

valve.

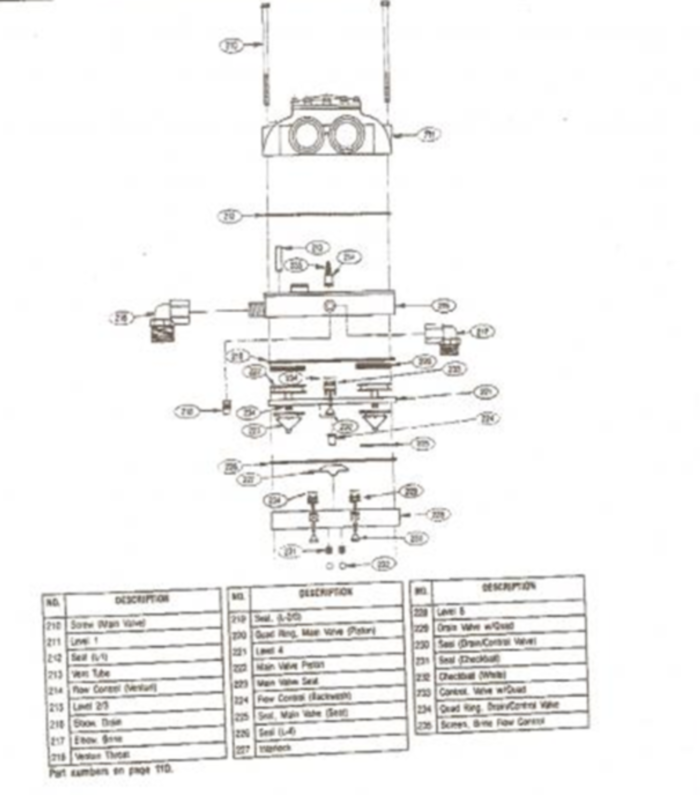

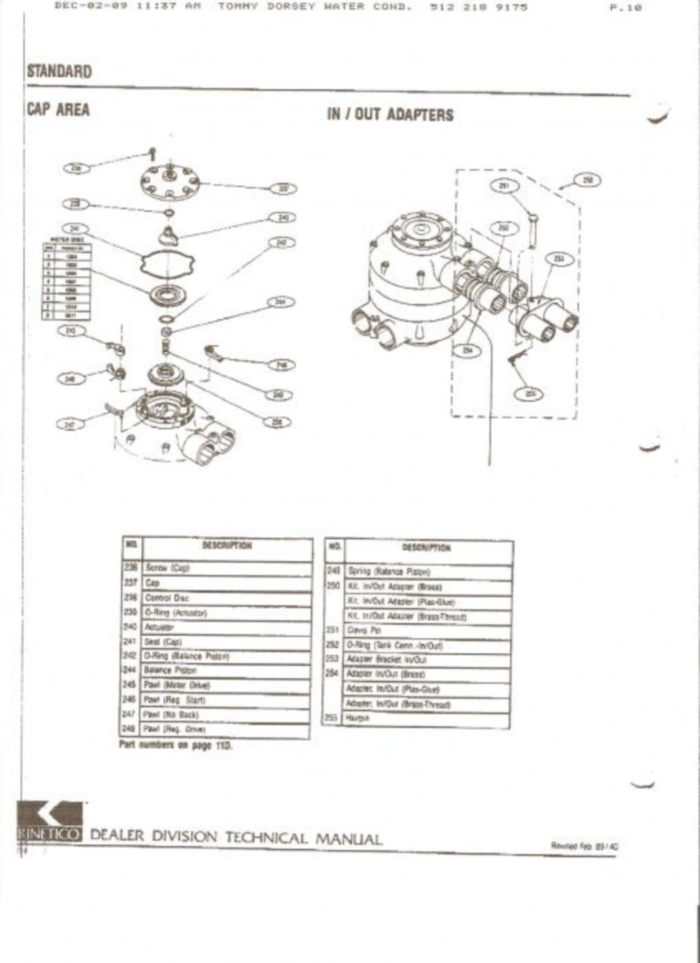

#2

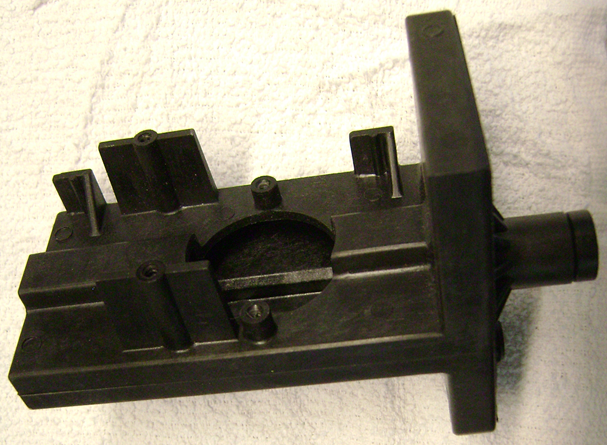

09.14.14 Here are the Kinetico Water Softener parts we carry. Have you ever heard the saying ‘A picture is worth 1,000 words’? Soon- more pictures of Kinetico Water Softener parts and services to arrive (all these will be posted) .

Kinetico water softener complete valve 1. Already been used (recycled) $200.00 plus tax

Kinetico water softener parts 2 ‘level 1’ part #211. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 3. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 4 ‘level 2/3’ part # 215. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 5. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 6. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 7. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 8. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 9. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 10. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 11 . Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 12 ‘valve screws’ part # 210. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 13. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 14 ‘disc’ part # 238. Already been used (recycled) $5.00 plus tax.

Kinetico water softener parts 15 (screw ‘cap’ part # 236). Already been used (recycled) 50 cents plus tax.

Kinetico water softener diagram 16. To show the assembly of these parts.

Kinetico water softener parts 17 ‘spring-piston’ part #249. Already been used (recycled) $1.00 plus tax.

Kinetico water softener parts 18. Already been used (recycled) 50 cents plus tax.

Kinetico water softener parts 19. Already been used (recycled) 50 cents plus tax.

Kinetico water softener parts 20. Already been used (recycled) 50 cents plus tax.

Kinetico water softener parts 21. Already been used (recycled) 50 cents plus tax.

Kinetico water softener parts 22. Already been used (recycled) $5.00 plus tax.

Kinetico water softener diagram 23. To show the assembly of these parts.

Kinetico water softener parts 24 ‘cap’ part # 237. Already been used (recycled) $5.00 plus tax.

08.08.14 Kinetico water softener. We have parts and perform service on this unit.

The above diagrams were taken from Google images; I typed in Kinetico parts diagrams. Brian Hayden Boyett BS, CWS-VI, CI

08.28.14 We will begin posting Kinetico parts that we recycle. If you need a Kinetico part we plan to inventory them all. If you buy your Kinetico parts from our company; the savings will be enormous.

08.29.14 10 AM. When we have enough Kinetico parts and components in our inventory we will begin providing these Kinetico Water softeners (and eventually Kinetico reverse osmosis units) on a rental basis for $30/mo plus tax. We will also sell these recycled units. The recycled units we sell will be ‘like new’. The price saving will be tremendous. In my opinion the retail prices of Kinetico units and parts require a large investment of money. We feel our recycling work with Kinetico parts, tanks and components – including cation resin replacement (resin change out on Kinetico Water Softeners; to change cation resin on Kinetico Water Softeners) and carbon media replacement (carbon media change out on Kinetico Water Softeners; to change the carbon media in a Kinetico Water Softener) will save our Kinetico clients thousands of dollars. We also feel with our expert technicians we will provide a very exceptional level of service and outstanding and friendly customer service. Our technicians are very communicative and responsive.

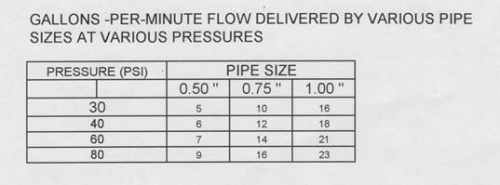

It is my opinion that Kinetico Water Softeners do not have enough cation resin media to effectively soften the hard Arizona water. We feel the most appropriate resin capacity (used continuously) is 64,000 grains. As I understand the present Kinetico residential water softeners being offered in this valley are much less than 64,000 grains (using 64,000 grains continuously ‘at the same time’). Therefore, based upon the flow rates of our pipes and appliances (please see this link for scientific data: http://www.azh2o.com/index.php?option=com_content&view=article&id=100) and the ability of ‘cation resin’ to soften the water; Kinetico water softeners may not be the most effective solution for our hard Arizona water. I’m just saying. However, we will be happy to help you keep your small Kinetico water softeners running. Kinetico water softeners regenerate constantly and waste much water. Please ask about our zero water waste whole house water treatment solution (which includes whole house carbon filtration for the entire home). We will provide you 100% chlorine free water with this water treatment method.

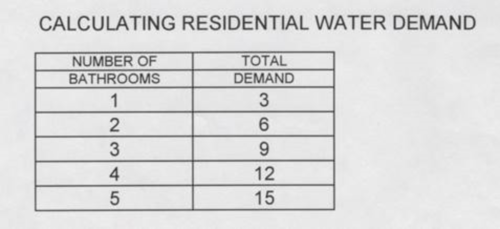

Source: the above two diagrams: ‘gallons – per – minute flow delivered by various pipe sizes at various pressures’ and ‘calculating residential water demand’ ( I found this information in my father’s file (William Brian Boyett ‘during his career he achieved the certification of CWS-V through the WQA.ORG’) titled Kinetico Water Softeners and Water Treatment equipment. He utilized this information when competing against the company known as Kinetico because their resin quantities are much smaller than ours and their units have a lower flow rate. For a single family home, or a business – both of these flaws can be a detriment when providing water treatment to an establishment.

This document was written and prepared by

Brian Hayden Boyett BS, CWS VI, CI

General Manager, Boyett’s Family Rayne Water Conditioning

Office: (480) 969-7251

Cell: (602) 291-4157

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

source: http://www.azh2o.com/index.php?option=com_content&view=article&id=100 (Theorigination date of this document is: 04.02.13)

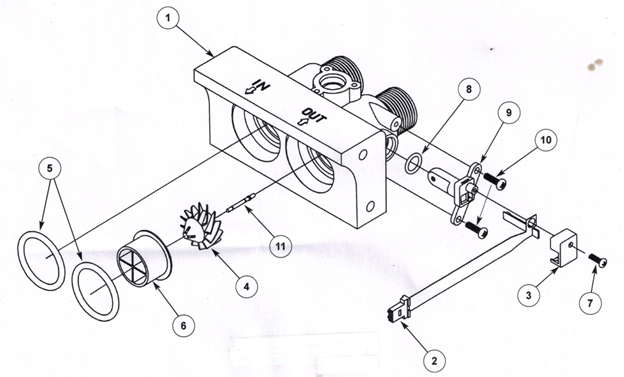

#3

08.08.15 Erie water softener. We have parts available at our office (for this equipment). We are qualified to perform service on this unit.

#4

08.08.14 Fleck 5600 (Econominder) Water Softener. We have all the parts on this unit and are prepared to perform service on this unit.

This has been one of the most dependable valves in our industry. This is the valve that we utilize on most our residential rental water softeners.

This valve was developed in the 1980’s by a company called Fleck Controls. Fleck Controls used be called L.W. FLECKENSTEIN, INC. and people would say often they had a “Fleckenstein valve.” They are now called “Fleck Controls” and are owned by Pentair Water, a world conglomerate of water-related companies. Fleck makes a large number of control valves for residential and commercial water softeners and backwashing filters, and have been a world leader in this technology for over 50 years. (this is a extract from a Fleck Controls marketing media).

This is a marketing brochure describing our 5600 valve.

10.21.15 9:15 AM

Model 5600 & 5600 Fleck Econominder®

Service Manual

Model 5600 & 5600 Econominder®

Model 5600 Econominder Installation and Start-up Procedures

NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’s recommendations and to meet applicable plumbing codes.

Manual Regeneration Knob 24-Hour Gear

Words in pictures:

Red Time Set Button

Manual Regeneration Knob

Program Wheel

24-Hour Gear

People Dial

White Dot

Grains Per Gallons Water Hardness Scale

Gallons Label

Model 5600 Econominder –

1Manually index the softener control to the In Service position and let water flow into the resin tank. When the water flow stops, open a softened water tap until all air is released from the lines. Then close tap.

NOTE: The various regeneration positions may be dialed manually by turning the knob on the front of the control until the indicator shows that the softener is in the desired position.

- Set water usage program wheel using anyone of the following procedures: Typical Residential Application

To program, just set the time, set the hardness and it automatically monitors system needs and regenerates only when necessary. To set time of day press red time set button and turn 24-hour gear until present time of day is at “time of day.” Set program wheel by lifting the “people” dial and rotating it so that the number of people in the household is aligned with the household grains per gallon water hardness. Release the dial and check for firm engagement at setting. This method provides reserve capacity based on 75 gallons per person.

– Optional Programming Procedures

Calculate the gallon capacity of the system, subtract the necessary reserve requirement and set the gallons available at the small white dot on program wheel gear. Note, drawing shows 850 gallon setting. The capacity (gallons) arrow denotes remaining gallons exclusive of fixed reserve.

- Rotate program wheel counterclockwise until it-stops at Regeneration position.

- Manually index the control to the Backwash position and allow water to flow at the drain for 3 or 4 minutes.

- Remove back cover plate.

- Make sure than the salt dosage is set as recommended by the manufacturer. Manually index the control to the Brine Fill position and allow the brine tank to fill to the top of the air check.

- Manually index the control to the Brine Rinse position and allow the control to draw water from the brine tank until it stops.

- Plug in the electrical cord and look in the sight hole in the back of the monitor to see that it is running.

- Manually advance the control to the beginning of the Brine Fill position and allow the control to return to the In Service position automatically.

- Fill the brine tank with salt.

- Replace back cover on the control. Be sure cable is not pinched between cover and housing.

- Make sure that any bypass valving is left in the normal In Service position.

Model 5600 & 5600 Econominder®

Model 5600 Control Valve Drive Assembly

Item Number No. Req ‘d Part Number Description

1 14448-010 housing, with pin

1 14448-011 housing, with pin drilled for screw

14448-012 housing, with pin drilled for thumb screw

IA 1 15494-01 “L” housing, with pin

15494-03 “L” housing, with pin drilled for designer

2 1 13175 motor mounting plate

3 1 18743 motor, 120V, 60 Hz

1 19659 motor, 24V 60 Hz

4 (2-3) 11384 screw, motor mtg. and ground wire

5 (3-5) 13296 screw, component mounting

6 1 13017 idler gear

7 1 13018 idler pinion

8 1 13312 spring, idler

9 1 13164 drive gear

11 1 13170 main gear and shaft

12 1 19205 24-hour gear assembly, silver

1 19205-01 24-hour gear assembly, tan

13 1 13011 cycle actuator gear

14 1 14177 knob, manual regeneration

15 4 13300 ball, 1/4″ dia.

16 2 13311 spring, detent, skipper wheel

19 1 14381 skipper wheel assembly, 12-day

1 14860 skipper wheel assembly, 7-day

20 1 13864 skipper wheel ring

21 2 14457 spring, detent, main gear

22 1 13014 regeneration pointer

23 1 11842 electrical cord, standard

24 2 12681 wire connector (not shown)

25 1 13547 strain relief

26 1 13229 back cover

27 1 13309 front label, brown on beige

1 13437 front label, blue/silver on black

28 1 13310 rear label, softener

1 18520 rear label, filter

29 1 13348 tape stripe, brown on beige

1 13436 tape stripe, blue on silver

30A 1 60514 brine cam assembly, 3-18

1 60514-01 brine cam assembly, 6-36

1 60514-02 brine cam assembly, minutes

34 2 12473 screw-drive mounting

35A 1 12037 washer

37 1 15151 screw, knob

38 1 14176 valve position dial, standard

1 14278 valve position dial, low water

1 15478 valve position dial, chemical filter

1 16715 valve position dial, filter

39 1 14175 knob label, beige

14207 knob label, silver

40A 1 40214 screw, brine cam

A Not used when a filter valve

Model 5600 & 5600 Econominder®

Model 5600 and 5600 Econominder Control Valve Drive Assembly

Item Number No. Req’d Part Number Description

2-4 13255 adapter clip (clock or meter)

2 5 13242 seal

S 17772 silicone seal

3 I 61400-12 valve body assembly, l”dist.

61400-11 valve body assembly, 3/4″ dist.

4 1 13304 o-ring, distributor tube, I”

10244 o-ring, distributor tube, 13/16″

5 1 12281 o-ring, top of tank

6 6 not assigned

7 4 14241 spacer

8 1 13247 piston, standard

1 13781 piston, low water

1 13852 piston, filter

9 1 10696 piston pin

10 1 13001 piston rod assembly

II 1 12953 piston retainer

12 1 13446 end plug assembly standard, white

13446-10 end plug assembly filter, black

13 1 13446-20 end plug assembly low water, gray

14 2 13315 screw, injector mounting

15 2 19228 adapter coupling

16* 4 13305 o-ring, adapter coupling

I7 2-4 13314 screw, adapter coupling (clock or meter)

18 1 • 12638 o-ring, drain

19 2 13301 o-ring, injector

20A 2 13302 0-ring, brine spacer

21 1 13303 0-ring, injector cover

22 1 13163 injector body

23A I 10913U injector nozzle, undrillcd

24 1 10914 injector throat, specify size

25 1 10227 injector screen

26 1 13166 injector cover

27 1 13172 brine valve stem

28 1 12626 brine valve seat

29 1 13165 brine valve cap

30 I 13167 brine valve spacer

31 1 12550 quad ring

32 1 11973 spring, brine valve

33 1 16098 washer, brine valve

34 1 11981-01 retaining ring

35 1 10329 BLFC fitting nut

36 1 10330 BLFC ferrule

37 1 10332 BLFC tube insert

38 1 12094 BLFC button, .25gpm

12095 BLFC button, .50 gpm

1 12097 BLFC button, 1.0gpm

39A 1 12977 ring, BLFC

40 1 13245 BLFC button retainer

41 1 13244 BLFC fitting, 3/8″

42 1 DLFC button, specify size

43 1 13173 DLFC button retainer

44 1 12767 screen, brine line

45 1 15348 o-ring, DLFC (not shown)

46 1 13497 air disperser

47 I 13546 end plug retainer

48 3 12112 screw

49 1 13363 washer

50 1 13296 screw

51A 1 13398 yoke, brass, I” NPT

1 13708 yoke, brass, 3/4″NPT

SIB 1 18706 yoke, plastic, I” NPT

1 18706-02 yoke, plastic 3/4″ NPT

52 I 13308 drain hose barb

53 1 13918 BLFC. plug

54A 1 13857 brine valve, plug

* not used with meter controls A used in backwash filter

Model 5600 & 5600 Econominder®

Model 5600 Econominder Control Valve Drive Assembly

Item Number No. Req ‘d Part Number Description

1 14448-000 housing, with roll pin

14488-001 housing, with pin drilled for screw

14448-0 housing, with pin drilled for thumb screw

IA 1 15494-01 ‘L” housing, with pin

15494-03 “L” housing, with pin drilled for designer

2 1 13175 motor mounting plate

3 1 18743 motor, 120V 60 Hz

1 13494 motor, 24V 60 Hz

4 2-3 11384 screw, motor mtg. and ground wire

5 2-4 13296 screw, component mounting

6 1 13017 idler gear

7 1 13018 idlerpinion

8 1 13312 spring, idler

9 1 13164 drive gear

11 1 13170 main gear and shaft

12 1 19205 24-hour gear assembly, silver

1 19205-01 24-hour gear assembly, tan

13 1 13802 cycle actuator gear

14 1 14177 knob, manual regeneration

15 2 13300 ball, 1/4″ dia.

16 2 14457 spring, detent

18 I 13748 screw, program wheel

19 1 60405-I5 program skipper wheel assembly, specify hardness capacity

20 1 13806 program wheel retainer

21 1 13953 cover label, program wheel

22 1 11842 –

23 2 12681 wire connector

24 1 13547 strain relief

25 1 13229 back cover

26 not assigned

27 1 13955 front label, beige

13958 front label, silver

28 1 13310 rear label, softener

18520 rear label, filter

29 1 13957 tape stripe, beige

13960 tape stripe, silver

30 1 60514 brine cam assembly, 3-18

60514-01 brine cam assembly, 6-36

1 60514-02 brine cam assembly, minutes

34 2 12473 screw-drive mounting

35 I 12037 washer

37 1 13830 drive pinion, program wheel

38 1 13831 clutch, drive pinion

39 1 14253 spring retainer

40 1 14276 spring

41 1 14043 cable assembly, standard

14910 cable assembly, extended, right angle

42 1 14176 valve position dial, standard

14278 valve position dial, low water

I 15478 valve position dial, filter

43 1 14175 knob label, beige

I 14207 knob label, silver

44 1 15151 screw, knob

45 1 40214 screw, brine cam

MODEL 5600 & 5600 ECONOMINDER

by-pass valve assembly, plastic

PARTS LIST

Parts for the Fleck 5600 (RF Series): By-Pass Valve Assembly (plastic)

ITEM NO. NO. REQ’D PART NO. DESCRIPTION

1 1 19723 By-Pass Valve Body, Plastic

2 1 11183 0 Ring, -015

3 1 19724 Cap, By-Pass

4 2 17512 Screw, Hex Washer Head, #6-24 x 3

5 2 17820 Plug, By-Pass

6 4 18661 O Ring, -218

7 2 18662 Retaining Ring

8 2 18660 0 Ring

9 2 13305 0 Ring, 119

10 2 13255 Clip, Mounting

11 2 13314 Screw, Hex Washer Head. 8-18 x5/8

12A 1 18706 Yoke, Plastic, 1″ NPT

18706-02 Yoke, Plastic, 3/4″ NPT

12B 1 13708 Yoke, 3/4″

1 18708NP Yoke, 3/4″ Nickel Plated

1 13398 Yoke, 1″

1 13398NP Yoke, 1″ Nickel Plated

Model 5600 & 5600 Econominder®

Bypass Valve Assembly, Brass

Here is some information regarding the 5600 bypass valve and components. We have all the parts and supplies to fix this bypass valve.

This is the part called the bypass boot.

This is my finger sticking through the hole.

This hole is caused by age and the chlorine (which the city puts in the water) breaks down the plastic.

There should be no hole.

The degradation of this part will cause the bypass valve to erroneously begin to leak.

If this happens – this may happen to you:

In our opinion; it is better to be proactive.

This part is inserted in this old 5600 bypass valve:

We sell the bypass boot for $15.00 plus tax. Please call to confirm we have this in stock.

Our office phone number is (480) 969-7251. Our address is: 38 East 5th Avenue, Mesa AZ 85210

Bypass Valve Assembly, Brass

Item Number No. Req ‘d Part Number Description

1 1 17290 bypass valve body, 3/4″

1 17290NP bypass valve body, 3/4″)

1 13399 bypass valve body, 1″

1 3399NP bypass valve body, 1″ (nickel-plated)

2 1 11726 seal, bypass

3 1 11972 plug, bypass

4 1 11978 side cover

5 1 13604-01 label

6 8 15727 screw

7 1 11986 side cover

8 1 11979 lever, bypass

9 1 11989 screw, hex head, 1/4-14

A good idea is to upgrade to this bypass valve. The flow rate is better and it comes with our Boyett’s Family Resin screen ‘world-wide invention’. No other water company offers this feature (The Boyett’s Family Resin screen). This is an image of the new bypass valve ‘with the Boyett’s Family Resin screen’:

The screen will help prevent significant plumbing problems and financial loss by protecting your home – if the lower collector breaks.

This new bypass valve is more dependable and has a better flow rate.

This is an image of a lower collector which has broken:

Model 5600 Econominder Meter Assembly

Item Number No. Req ‘d Part Number Description

1 4 12473 screw, meter cover assembly

2A 1 14038 meter cover assembly, standard

213 1 15659 meter cover assembly, extended range (right angle)

3 1 13847 0-ring, meter cover assembly

4 1 13509 impeller

5 4 13314 screw, adapter clip

6 4 13255 adapter clip

7 1 13821 meter body

8 4 13305 0-ring, meter body

9 1 14613 flow straightener

This 5600 water softener (in Mesa, AZ; Chandler, AZ; Phoenix, Arizona; Cave Creek, AZ) is also known as an Ultima Water softener – distributed by a famous water treatment manufacture named B and R Industries (BR Industries, B and R Water softeners and RO units Mesa, Arizona, Phoenix, Arizona, Glendale, Arizona).

Model 5600 & 5600 Econominder®

Service Instructions

Replace Time Brine Valve, Injectors and Screen

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the valves at the conditioner inlet and outlet.

If the conditioner has an integral bypass valve, put it in the Bypass position. If there is only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control to the In Service position.

- Disconnect brine tube and drain line connections at the injector body.

- Remove the two injector body mounting screws. The injector and brine module can now be removed from the control valve. Remove and discard valve body o-rings.

- Replace brine valve.

Pull brine valve from injector body, also remove and discard o-ring at bottom of brine valve hole. Apply silicone lubricant to new o-ring and reinstall at bottom of brine valve hole.

Apply silicone lubricant to o-ring on new valve assembly and press into brine valve hole, shoulder on bushing should be flush with injector body.

- Replace injectors and screen.

Remove injector cap and screen, discard o-ring. Unscrew injector nozzle and throat from injector body. Screw in new injector throat and nozzle, be sure they are seated tightly. Install a new screen.

Apply silicone lubricant to new o-ring and install around oval extension on injector cap.

- Apply silicone lubricant to three new o-rings and install over three bosses on injector body.

- Insert screws with washers through injector cap and injector. Place this assembly through hole in timer housing and into mating holes in the valve body. Tighten screws. (Be sure to reinstall brass spacers with injector on model 4600 valve.)

- Reconnect brine tube and drain line.

- Return bypass or inlet valving to normal In Service position. Water pressure automatically builds in the conditioner. NOTE: Be sure to shut off any bypass line.

- Check for leaks at all seal areas. Check drain seal with the control in the Backwash position.

- Plug electrical cord into outlet.

- Set time of day and cycle the control valve manually to assure proper function.

— Make sure control valve is in the In Service position.

- Make sure there is enough brine in the brine tank.

- Rotate program wheel counterclockwise until it stops at Regeneration position.

- Start regeneration cycle manually if water is hard.

Model 5600 & 5600 Econominder®

Service Instructions (Contd.)

Replace Timer

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

– If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the. valves at the conditioner inlet and outlet.

– If the conditioner has an integral bypass valve, put it in the Bypass position. If there is only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control to the In Service position.

- Pull cable out of meter cover. Remove the control valve back cover.

- Remove screw and washer at drive yoke. Remove timer mounting screws. The entire timer assembly now lifts off easily.

- Put new timer on top of valve. Be sure drive pin on main gear engages slot in drive yoke (rotate control knob if necessary).

- Replace timer mounting screws. Replace screw and washer at drive yoke.

- Return bypass or inlet valying to normal In Service position. Water pressure automatically builds in the conditioner. NOTE: Be sure to shut off any bypass line.

- Plug electrical cord into outlet.

- Set time of day, program wheel, and salt usage. Cycle the control valve manually to assure proper function. Be sure to return the control valve to the In Service position.

- Replace the control valve back cover. Be sure grommet at cable hole is in place.

- Make sure there is enough brine in the brine tank.

- Rotate program wheel counterclockwise until it stops at Regeneration position.

- Start regeneration cycle manually if water is hard.

- Plug cable into meter cover, rotate cable to align drive flat if necessary.

Model 5600 & 5600 Econominder®

Service Instructions (Contd.)

Replace Piston Assembly

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the valves at the conditioner inlet and outlet.

If the conditioner has an integral bypass valve, put it in the Bypass position. – If there is only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control to the In Service position.

- Pull cable out of meter cover. Remove the control valve back cover.

- Remove screw and washer at drive yoke. Remove timer mounting screws. The entire timer assembly now lifts off easily. Remove end plug retainer plate.

- Pull upward on end of piston yoke until assembly is out of valve.

- Inspect the inside of the valve to make sure that all spacers and seals are in place, and that there is no foreign matter that would interfere with the valve operation.

- Take new piston assembly as furnished and push piston into valve by means of the end plug. Twist yoke carefully in a clockwise direction to properly align it with drive gear. Replace end plug retainer plate.

- Place timer on top of valve. Be sure drive pin on main gear engages slot in drive yoke (rotate control knob if necessary).

- Replace timer mounting screws. Replace screw and washer at drive yoke.

- Return bypass or inlet valving to normal In Service position. Water pressure automatically builds in the conditioner. NOTE: Be sure to shut off any bypass line.

- Plug electrical cord into outlet.

- Set time of day, program wheel, and salt usage. Cycle the control valve manually to assure proper function. Be sure to return the control valve to the In Service position.

- Replace the control valve back cover. Be sure grommet at cable hole is in place.

- Make sure there is enough brine in the brine tank.

- Rotate program wheel counterclockwise until it stops at Regeneration position.

- Start regeneration cycle manually if water is hard.

- Plug cable into meter cover. Rotate cable to align drive flat if necessary.

Model 5600 & 5600 Econominder®

Service Instructions (Contd.)

Replace Seals and Spacers

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the valves at the conditioner inlet and outlet.

– If the conditioner has an integral bypass valve, put it in the Bypass position. – If there as only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control to the In Service position.

- Pull cable out of meter cover. Remove the control valve back cover.

- Remove screw and washer at drive yoke. Remove timer mounting screws. The entire timer assembly now lifts off easily. Remove end plug retainer plate.

- Pull upward on end of piston rod yoke until assembly is out of valve. Remove and replace seats and spacers with fingers.

Model 5600 & 5600 Econominder®

Service Instructions (Contd.)

Replace Meter

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the

valves at the conditioner inlet and outlet.

If the conditioner has an integral bypass valve, put it in the Bypass position.

If there is only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control

to the In Service position.

- Pull cable out of meter cover.

- Remove two screws and clips at bypass valve or yoke. Pull resin tank away from plumbing Connections.

- Remove two screws and clips at control valve. Pull meter module out of control valve.

- Apply silicone lubricant to four new 0-rings and assemble to four ports on new meter module.

- Assemble meter to control valve.Note, meter portion of module must be assembled at valve outlet.

- Attach two clips and screws at control valve. Be sure clip legs are firmly engaged with lugs.

- Push resin tank back to the plumbing connections and engage meter ports with bypass valve or yoke.

- Attach two clips and screws at bypass valve or yoke. Be sure clip legs are firmly engaged with lugs.

- Return bypass or inlet valving to normal In Service position. Water pressure automatically builds in the conditioner. NOTE: Be sure to shut off any bypass line.

- Check for leaks at all seal areas.

- Plug electrical cord into outlet.

- Set time of day.

– Make sure control valve is in the In Service position.

- Rotate program wheel counterclockwise until it stops at Regeneration position.

- Start regeneration cycle manually if water is hard.

- Plug cable into meter cover. Rotate cable to align drive flat if necessary.

Model 5600 & 5600 Econominder®

Service Instructions (Contd.)

Replace Meter Cover and/or Impeller

- Unplug electrical cord from outlet.

- Turn off water supply to conditioner:

If the conditioner installation has a “three valve” bypass system, first open the valve in the bypass line, then close the valves at the conditioner inlet and outlet.

– If the conditioner has an integral bypass valve, put it in the Bypass position If there is only a shut-off valve near the conditioner inlet, close it.

- Relieve water pressure in the conditioner by putting the control in the Backwash position momentarily. Return the control to the In Service position.

- Pull cable out of meter cover.

- Remove four screws on cover

- Lift cover off of meter module, discard o-ring.

- Remove and inspect impeller for gear or spindle damage, replace if necessary.

- Apply silicone lubricant to new 0-ring and assemble to the smallest diameter on meter cover.

- Assemble cover to meter module. Be sure impeller spindle enters freely into cover. Press firmly on cover and rotate if necessary to assist in assembly.

- Replace four screws and tighten.

- Return bypass or inlet valving to normal In Service position. Water pressure automatically builds in the conditioner. NOTE: Be sure to shut off any bypass line.

- Check for leaks at all seal areas.

- Plug electrical cord into outlet.

- Set time of day.

Make sure control valve is in the In Service position.

- Rotate program wheel counterclockwise until it stops at Regeneration position.

- Start regeneration cycle manually if water is hard.

- Plug cable into meter cover. Rotate cable to align drive flat if necessary.

Model 5600 & 5600 Econominder®

Model 5600 and 5600 Econominder Troubleshooting

PROBLEM CAUSE CORRECTION

1.Softener fails to regenerate. A.Electrical service to unit has been A.Assure

interrupted. permanent electrical

service

(check fuse, plug, pull chain

or

switch).

B.Timer is defective. B. Replace timer.

- Power failure. C.Reset time of day.

2.Softener delivers hard water. A.Bypass valve is open. A.Close bypass valve.

B.No salt in brine tank. B. Add salt to brine tank and

Maintain salt level above

water level.

- Injectors or screen is plugged. C.Replace injectors and

screen.

D.Insufficient water flowing into brine tank. D.Check brine tank fill time

and clean

brine line flow control if plugged.

E.Hard water tank hardness. E.Repeated flushings of the

hot water

tank is required.

F.Leak at distributor tube. F.Make sure distributor tube is

Not cracked. Check 0-ring and

tube pilot.

G.Internal valve leak. G.Replace seals and spacers and/or

piston.

3.Unit uses too much salt. A.Improper salt setting. A.Check salt usage and salt setting.

B.Excess water in brine tank. B.See problem number 7.

4.Loss of water pressure A.Iron build-up in line to water conditioner. A.Clean line to water

conditioner.

B.Iron build-up in water conditioner. B.Clean control and add resin

cleaner to

resin bed. Increase frequency of

regeneration.

- Inlet of control plugged due to foreign C.Remove piston and clean

material loose from pipes by recent work control.

done on plumbing system.

5.Loss of resin through drain line. A.Air in water system. A.Assure that well system has

proper air elimination control,

check for dry well condition.

6.Iron in conditioned water. A.Fouled resin bed. A.Check backwash, brine draw and

brine tank fill, increase frequency of

regeneration, increase backwash

time.

7.Excessive water in brine tank. A.Plugged drain line flow control. A.Clean flow control.

8.Salt water in service line. A.Plugged injector system. A.Clean injector and replace screen.

B.Timer not cycling. B. Replace timer.

- Foreign material in brine valve. C.Clean or replace brine valve.

D.Foreign material in brine line flow control. D.Clean brine line flow

control.

Model 5600 & 5600 Econominder®

Model 5600 and 5600 Econominder Troubleshooting (Contd.)

PROBLEM CAUSE CORRECTION

9.Softener fails to draw brine. A.Draw line flow control is plugged. A.Clean drain line

flow control.

B.Injector is plugged. B.Clean or replace injectors.

C.Injector screen plugged. C.Replace screen.

D.Line pressure is too low. D. Increase line pressure

(minimum 20

psi at all times).

- Internal control leak. E.Change seals, spacers

and/or piston

assembly.

- Control cycles continuously. A.Faulty timer mechanism. A.Replace timer.

11.Drain flows continuously. A.Foreign material in control. A.Remove piston assembly

and inspect

bore, remove foreign

material and

check control in various

regeneration positions.

B.Internal control leak. B. Replace seals and/or

piston assembly.

- Control valve jammed in Brine or C.Replace seals and/or piston

Backwash position. assembly.

D.Timer motor stopped or jammed. D.Replace timer.

General Service Hints for Meter Control

PROBLEM CAUSE CORRECTION

Softener delivers hard water. A.Reserve capacity has been exceeded. A.Check salt dosage

requirements and

reset program wheel to

provide

additional reserve.

B.Program wheel is not rotating with meter B.Pull cable out of

output. meter cover and

rotate manually, program

wheel must move without

binding and clutch must give

positive “clicks”

when program wheel strikes

regeneration stop (if not, replace

timer).

C.Meter is not measuring flow. C.Check output by observing

rotation

of small gear on front of timer

(program wheel must not be against

regeneration stop for this check)

each tooth to tooth is approximately

30 gallons (if not, replace meter).

Model 5600 & 5600 Econominder®

Model 5600SF Troubleshooting

PROBLEM CAUSE CORRECTION

1.Filter fails to backwash. A.Electrical service to unit has been A.Assure permanent

interrupted. electrical service

(check fuse, plug, pull chain or

switch).

B.Timer is defective. B. Replace timer.

- Power failure. C.Reset time of day.

2.Filter “bleeds” iron. A.Bypass valve is open. A.Close bypass valve.

B.Excessive water usage. B. Reduce days between,

backwashing

(see timer instructions), make sure

that there is not a leaking valve in the

toilet bowl or sinks.

- Hot water tank rusty. C.Repeated flushings of the

hot water tank is required.

D.Leak at distributor tube. D.Make sure distributor tube

is not cracked, check 0-ring

and tube pilot.

E.Defective or stripped filter medium bed. E.Replace bed.

F.Inadequate backwash flow rate. F.Make sure filter has

correct drain

flow control, be sure flow control

is not clogged or drain

line restricted, be sure water

pressure has not dropped, increase

backwash flow rate according to

specifications for your

unit, see your dealer for

recommendations.

- Loss of water pressure. A.Iron or turbidity build-up in water filter. Reduce days

between backwashing

so filter backwashes more often,

make sure filter is sized large enough

to handle water usage.

B.Inlet plugged due to foreign material B.Remove piston and clean control.

broken loose from pipes by recent work

done on plumbing system.

4.Loss of filter medium through A.Broken or missing top screen. A.Replace top screen, must

have 0.020″ drain line, wide slots.

5.Drain flows continuously. A.Foreign material in control. A.Remove piston assembly and

Inspect bore, remove foreign

material and

check control in various cycle

positions.

B.Internal control leak. B. Replace seals and/or piston

assembly.

- Control valve jammed in rinse or C.Replace piston, seals and

spacers

backwash. (and drive motor if necessary).

Model 5600 & 5600 Econominder®

Service Assemblies

Part Number Description

60102-00 piston, softener

60102-10 piston, filter

60102-20 piston, low water

60125 seal kit

60084-XX injector

60032 brine valve

60514 brine cam, 3-18

60514-01 brine cam, 6-36

60514-02 brine cam, minutes

60510 coupling, with clip and screws

60040 bypass, brass 3/4″ NPT

60041 bypass, brass 1″ NPT

60049 bypass, plastic

60086 meter, standard

60087 meter, extended

160136-5600 service kit, meter

160135-5600 service kit, clock

14860 skipper wheel, 7-day

14381 skipper wheel, 12-day

60405-10 meter program wheel, standard

60405-20 meter program wheel, extended

Parts for the Fleck 5600 Fleck (Rayne RF Series): Complete assemblies

PART NO. DESCRIPTION

60022-50 BRINE LINE FLOW ASSEMBLY

60032 BRINE VALVE

61020 BRINE VALVE ASSEMBLY (SHURZ)

60040 3/4″ BYPASS VALVE

60041 1″ BYPASS VALVE

60084 INJECTOR/ DRAIN MODULE

60086 METER MODULE COMPLETE

14038 METER COVER ASSEMBLY

60102-00 PISTON ASSEMBLY (STANDARD)

60102-20 PISTON ASSEMBLY (LOW FLOW)

60125 SEAL KITS

60514 BRINE CAM ASSEMBLY

60354-00 POWER HEAD METER

60353-00 POWER HEAD T/C

COMPLETE VALVE AND POWER HEAD

METER NO B.P.

COMPLETE VALVE AND POWER HEAD T/C

NO B.P.

13708 3/4″ BOSS ADAPTER

13398 1″ BOSS ADAPTER

13400 110 VOLT MOTOR

13494 24 VOLT MOTOR

13170 MAIN GEAR AND SHAFT

13168 BRINE CAM

14043 METER CABLE

13830 DRIVE PINION

13831 CLUTCH PINION

14253 SPRING RETAINER

14276 SPRING

11726 BY-PASS BOOT

60225-01 DUST COVER FOR TIMER (STANDARD)

60226-11 COVER FOR L STYLE TIMER

61400-12 VALVE BODY ONLY – 1″ DISTRIBUTOR

61400-11 VALVE BODY ONLY – 3/4″ DISTRIBUTOR

5600 OWNERS SERVICE MANUAL

Fleck 5600 Valve ( and Rayne RF Series)

This 5600 valve is so dependable we refer to this valve performance as bullet proof. Because of this dependability we utilize this valve on most of our rental water softeners.

This is an image of cation resin beads taken under a microscope.

We recently sent a sample of cation resin (water softener media) to a laboratory for testing purposes. This is a description of the test performed.

MICROSCOPIC BEAD EXAMINATION:

A sample of the resin is placed under the microscope for determination of the physical integrity of the resin and contamination of the bead.

#5

08.08.15 Fleck 5000SE. We have all the parts necessary to rebuild this unit (including the cation resin). We also carry the turbines (these are prone to fail in Arizona ‘because of the corrosive water’).

09.02.14 A common problem we are finding, on this unit, is that it is not reading the gallons (the gallons do not count down). This can cause hard water. The solution; replace the turbine. These turbines are problematic and need to replaced often.

Another problem we are experiencing with this type unit is error codes. If you ever receive an error code on this unit please call us (480) 969-7251 or e mail me This email address is being protected from spambots. You need JavaScript enabled to view it. and we will help you develop a solution to this problem.

10.28.15 1:45 PM

ProFloSE Downflow brining service manual water softener (fleck 5000SE water softener)

ProFloSE Downflow brining service manual water softener (fleck 5000SE water softener)

General Residential Installation Check List

WATER PRESSURE: A minimum of 20 psi inlet water pressure is required for regeneration valve to operate effectively

ELECTRICAL FACILITIES: An uninterrupted alternating current (A/C) supply is required. Please make sure your voltage supply is compatible with your unit before installation.

EXISTING PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up heavily with lime and/or iron should be replaced. If piping is clogged with iron, a separate iron filter unit should be installed ahead of the water softener.

LOCATION OF SOFTENER AND DRAIN: The softener should be located close to a clean working drain and connected according to local plumbing codes.

BY-PASS VALVES: Always provide for the installation of a by-pass valve if unit is not equipped with one.

CAUTION: Water pressure is not to exceed 120 p.s.i., water temperature is not to exceed 11000017, and the unit cannot be subjected to freezing conditions.

Valve Installation and Start-up Procedures

INSTALLATION INSTRUCTIONS

1 Place the softener tank where you want to install the unit making sure the tanks are level and on a firm base

- All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should be a minimum of 1/2″. Backwash flow rates in excess of 7 gpm or length in excess of 20′ require 3/4″ drain line.

- The 1″ distributor tube (1.050 O.D.) should be cut flush with top of tank.

- Lubricate the distributor o-ring seal and tank o-ring seal. Place the main control valve on tank. Note: Only use silicone lubricant.

5 Solder joints near the drain must be done prior to connecting the Drain Line Flow Control fitting (DLFC) Leave at least 6″

between the DLFC and solder joints when soldering pipes that are connected on the DLFC Failure to do this could cause interior damage to the DLFC.

- Teflon tape is the only sealant to be used on the drain fitting.

- Make sure that the floor is clean beneath the salt storage tank and that it is level.